Introduction to Insulation Render and Concrete Rendering

Insulation render and concrete rendering are two essential components in modern construction that work together to provide superior thermal protection for buildings. While concrete rendering offers a durable and aesthetically pleasing finish to the exterior of a building, insulation render enhances its thermal performance, reducing energy consumption and improving overall comfort.

The Importance of Thermal Insulation in Buildings

Thermal insulation is crucial in maintaining a comfortable indoor environment while minimising energy costs. By reducing heat transfer between the interior and exterior of a building, insulation helps to keep the indoor temperature stable, regardless of the weather conditions outside.

Benefits of Proper Insulation

- Reduced energy consumption and lower utility bills

- Improved indoor comfort throughout the year

- Minimised environmental impact by reducing carbon emissions

- Extended lifespan of the building’s heating and cooling systems

Understanding Concrete Rendering

Concrete rendering is a popular choice for exterior wall finishes due to its durability, versatility, and aesthetic appeal. It involves applying a mixture of cement, sand, and water to the surface of a building, creating a smooth and uniform appearance.

Advantages of Concrete Rendering

- Protects the underlying structure from weathering and damage

- Offers a wide range of textures and colours for customization

- Provides a low-maintenance and long-lasting solution

- Enhances the overall value and appearance of the building

The Role of Insulation Render

Insulation render is a specialised type of rendering that incorporates insulating materials, such as polystyrene beads or mineral wool, into the render mix. This combination creates a thermally efficient layer on the exterior of the building, reducing heat transfer and improving energy efficiency.

How Insulation Render Works

- Insulating materials are mixed into the render, creating air pockets that reduce heat transfer

- The render is applied to the exterior of the building, forming a continuous insulating layer

- The insulation render works in conjunction with the concrete rendering to provide both thermal protection and a durable finish

Benefits of Combining Insulation Render with Concrete Rendering

When used together, insulation render and concrete rendering offer numerous benefits for both new construction and renovation projects.

Enhanced Thermal Performance

- Insulation render significantly improves the thermal performance of the building envelope

- Reduces heat loss in winter and heat gain in summer, maintaining a comfortable indoor environment

- Minimises thermal bridging, preventing cold spots and condensation issues

Improved Energy Efficiency

- The combination of insulation render and concrete rendering reduces the load on heating and cooling systems

- Lower energy consumption translates to reduced utility bills and a smaller carbon footprint

- Helps buildings meet increasingly stringent energy efficiency regulations

Increased Durability and Protection

- Insulation render provides an additional layer of protection against weathering and external damage

- The render system helps to prevent moisture intrusion, minimising the risk of damp and mould growth

- The combined strength of concrete rendering and insulation render extends the lifespan of the building’s exterior

Choosing the Right Insulation Render System

When selecting an insulation render system, it is essential to consider factors such as the building’s location, climate, and specific thermal performance requirements.

Types of Insulation Render

- Expanded Polystyrene (EPS) render: Lightweight and cost-effective, with good thermal insulation properties

- Mineral wool render: Fire-resistant and environmentally friendly, with excellent acoustic insulation

- Phenolic foam render: High-performance insulation with a low thermal conductivity value

Thickness and Thermal Performance

- The thickness of the insulation render layer directly impacts its thermal performance

- Thicker layers provide better insulation but may require additional support and fixings

- The desired U-value (thermal transmittance) should be considered when determining the appropriate thickness

Compatibility with Concrete Rendering

- Ensure that the chosen insulation render system is compatible with the concrete rendering products and techniques used

- Consider factors such as adhesion, flexibility, and moisture resistance to ensure a long-lasting and effective result

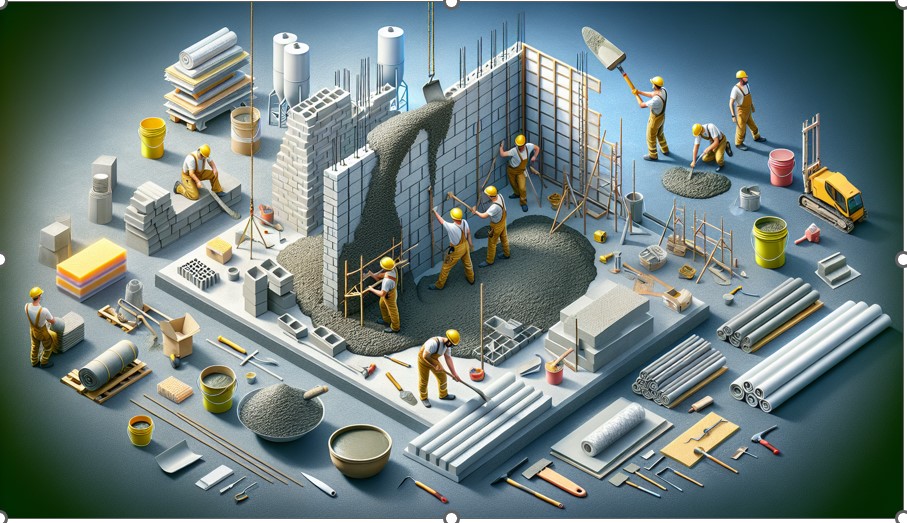

Installation Process for Insulation Render and Concrete Rendering

The installation of insulation render and concrete rendering should be carried out by experienced professionals to ensure optimal results and long-term performance.

Surface Preparation

- The substrate must be clean, dry, and free from debris and loose material

- Any cracks or damage should be repaired prior to the application of the render system

- A suitable primer may be required to improve adhesion and reduce suction

Application of Insulation Render

- The insulation render is mixed according to the manufacturer’s instructions

- The render is applied to the prepared surface using a trowel or spray machine

- The thickness of the insulation render layer is built up in stages, allowing for drying time between coats

Application of Concrete Rendering

- Once the insulation render has dried and cured, the concrete rendering is applied

- The rendering mix is prepared and applied in layers, building up the desired thickness

- The surface is levelled and smoothed using a straight edge or float

- Textured finishes can be achieved using various tools and techniques

Curing and Finishing

- Both the insulation render and concrete rendering require adequate curing time to achieve their full strength and performance

- The surface should be protected from rain, frost, and direct sunlight during the curing process

- A suitable finish, such as paint or sealant, may be applied once the rendering has fully cured

Maintenance and Repair of Insulation Render and Concrete Rendering

Regular maintenance and timely repairs are essential to ensure the long-term performance and appearance of the insulation render and concrete rendering system.

Regular Inspection and Cleaning

- Inspect the rendered surface annually for signs of damage, cracks, or deterioration

- Clean the surface using a low-pressure water spray and a mild detergent solution

- Avoid using abrasive cleaners or high-pressure washers, which can damage the render

Repairing Damage and Cracks

- Minor cracks and chips can be repaired using a suitable filler or patching compound

- Larger areas of damage may require the removal and replacement of the affected render

- Ensure that repairs are carried out using compatible materials and techniques to maintain the integrity of the system

Building Regulations and Standards for Insulation Render

Insulation render systems must comply with relevant building regulations and standards to ensure their safety, performance, and environmental impact.

Thermal Performance Standards

- Building regulations specify minimum thermal performance requirements for external walls

- Insulation render systems must demonstrate compliance with these standards through U-value calculations and thermal bridging assessments

Fire Safety Regulations

- The fire performance of insulation render systems is regulated by building codes and standards

- The render system must meet the required fire resistance ratings and limit the spread of flames and smoke in the event of a fire

Environmental Impact and Sustainability

- Insulation render systems should be designed and installed with consideration for their environmental impact

- The use of sustainable materials, such as recycled or bio-based insulation, can help to reduce the carbon footprint of the building

- The improved energy efficiency provided by insulation render contributes to the overall sustainability of the built environment

Case Studies and Real-World Applications

Insulation render and concrete rendering have been successfully applied in various projects worldwide, demonstrating their effectiveness in improving thermal performance and energy efficiency.

Residential Buildings

- Single-family homes and multi-unit dwellings have benefited from the installation of insulation render systems

- Homeowners have reported significant reductions in energy bills and improved indoor comfort

- The aesthetic appeal of concrete rendering has also contributed to increased property values

Commercial and Industrial Facilities

- Office buildings, schools, and hospitals have utilised insulation render to meet stringent energy efficiency requirements

- The improved thermal performance has resulted in lower operating costs and reduced environmental impact

- The durability and low maintenance of concrete rendering have made it a popular choice for high-traffic commercial facilities

Historic Buildings and Renovations

- Insulation render has been successfully used in the renovation of historic buildings, where improving thermal performance is challenging

- The render system can be applied to the exterior of the building without compromising its historic character and architectural features

- The combination of insulation render and concrete rendering has helped to extend the lifespan of many historic structures while improving their energy efficiency

Future Developments and Innovations in Insulation Render

As the demand for energy-efficient and sustainable building solutions continues to grow, insulation render systems are likely to evolve and improve in the coming years.

Advanced Insulation Materials

- Researchers are developing new insulation materials with enhanced thermal properties and environmental sustainability

- Nanotechnology and phase change materials may be incorporated into insulation render systems to further improve their performance

Integrated Renewable Energy Solutions

- The integration of renewable energy systems, such as solar panels or heat pumps, with insulation render could provide a comprehensive approach to energy efficiency

- The render system could be designed to accommodate and support these integrated technologies

Smart Monitoring and Control Systems

- The incorporation of sensors and monitoring systems into insulation render could offer real-time data on the thermal performance of buildings. These systems could help optimise energy use by adjusting heating, cooling, or insulation levels based on environmental conditions and occupancy patterns.

Conclusion

Insulation render, when combined with concrete rendering, offers a comprehensive solution for achieving superior thermal protection, energy efficiency, and durability in buildings. Together, they not only provide an attractive and robust exterior finish but also significantly enhance the thermal performance of structures, leading to reduced energy consumption and improved indoor comfort.

As building regulations continue to evolve and the demand for energy-efficient solutions grows, the importance of insulation render systems will only increase. Innovations in insulation materials, integration with renewable energy, and the potential for smart monitoring systems will further improve the effectiveness and sustainability of insulation rendered in modern construction.

For both new builds and renovation projects, investing in insulation render and concrete rendering can provide long-lasting benefits, from cost savings on energy bills to increased property value and compliance with stringent energy standards.